- Browse Categories

- Insulated Electric Wire

- Power Cable

- Communication Cable

- Medical Grade Cable

- Optical Fiber Cable

- Aerial Cable

- Instrument Control Cable

- Rubber Cable

- Fire Rated Cable

- New Energy Cable

- AS/NZS Cable

- UL Cable

- Portable Power Station and LED light

- Subscribe

-

Get email updates on new products

- Latest News

-

Merry Christmas and Happy New Year 2026

Himake Cable wishes all of our Customers and Friends Merry Christmas and Happy New Year 2026!Why is HIMAKE a better partner of Electrical wire cable for you???

HIMAKE is a better partner of Electrical wire and Power cable for you always, it is a global Power and Communication Solution Provider!Good news, Big promotion

Good news, Big promotion! Good news, Big promotion! Good news, Big promotion! To show thanks to our customers, all products, w...What is the best cable for cold weather?

The arctic grade cable of HIMAKE is a very good weather proof and cold resistant cable that is ideally suited for extreme cold temperature applications.Belt and Road forum for International cooperation

The Belt and Road Forum for International Cooperation opened in Beijing on the May 14th 2017, President Xi delivered keynote speech at Belt an...Copper price had a big increase, order earlier to avoid higher copper price

Copper price increased much in the past days , many orders to HIMAKE CABLE from customers for avoiding the higher copper price, busy now! http...Himake fire rated cable samples all passed the quality inspection done by Market Quality Supervision

Good news, Himake fire rated cable samples all passed the quality inspection done by Market Quality Supervision office! Based on "Top quality with mos...Himake Cable was awarded with title of Market Quality Products

The local Quality Inspection Association had done a random cables quality inspection from the market, all Himake Cable got 100% pass, and all ...Himake cable worthy of your trust

Himake International Industry Limited is a leading company specializing in Electric wire and Power cable manufacturing, R&D, Sale and Service since 2...Himake Cable was honorably invited to Finance Service Forum

On the 5th November 2016, Himake Cable was honorably invited to join the Finance Service Forum hosted by Shenzhen Onetouch Business Service Ltd....

- Certifications

-

- Contact Us

-

Add: No.168,Longgang Road,Longgang District,Shenzhen,China 518116

Tel: +86 755 8521 6656

Mobile phone: +86 150 1259 7988

Skype: billzhoubiz

QQ: 452597086

E-mail: info@himakecable.com Contact Now

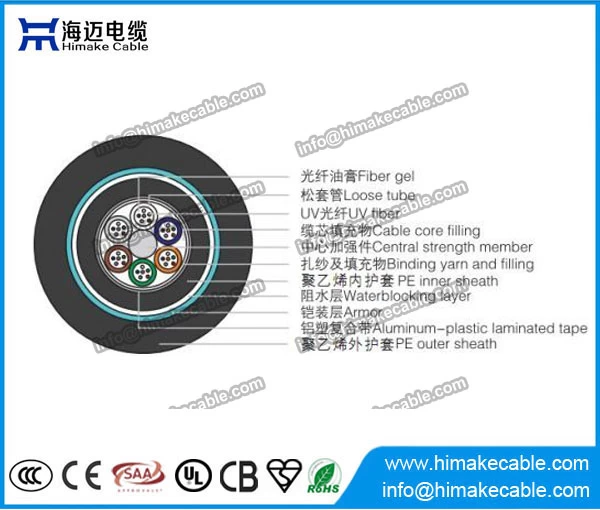

2-288 cores Stranded Loose tube armored Cable GYTA53

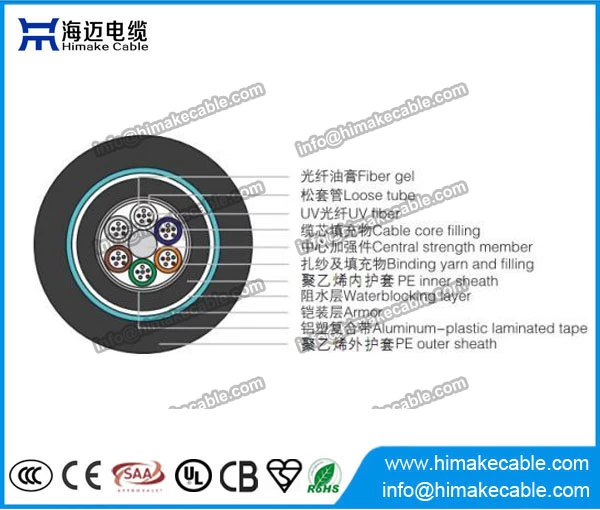

- 2~228 fibers, jelly filled, fiber contained central loose tube

- Fiber, 250um

- A metallic member in the cable center

- APL around the cable cores

- PE inner sheath, PSP armored

- PE outer sheath

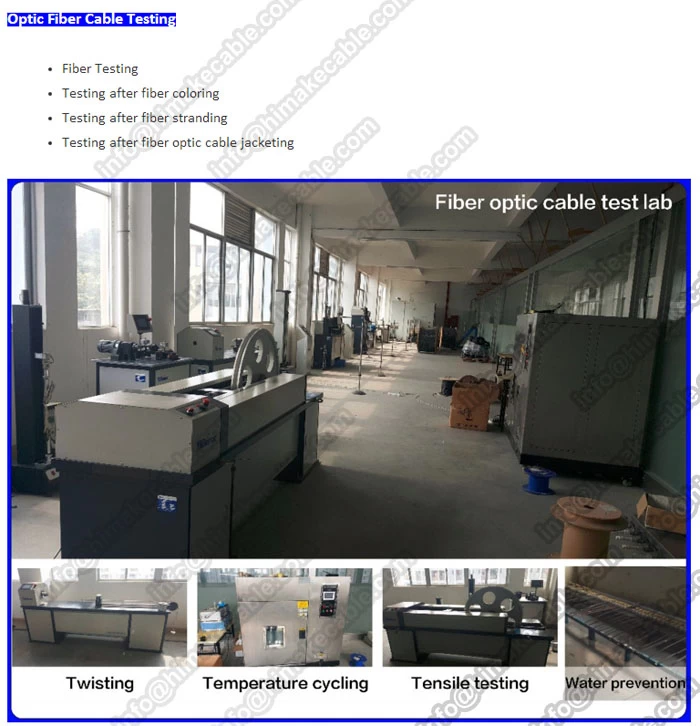

- Standard: YD/T 901-2001, IEC60794-1

- Certificate: ISO9001,CE,UL,SGS

- Leat time: 15~35 working days, it depends the order quantity

- Price term: FOB, CFR, CIF,EX-Works

- Payment term:T/T,LC at sight,West Union

- MOQ:10000 meters, trial order can be available

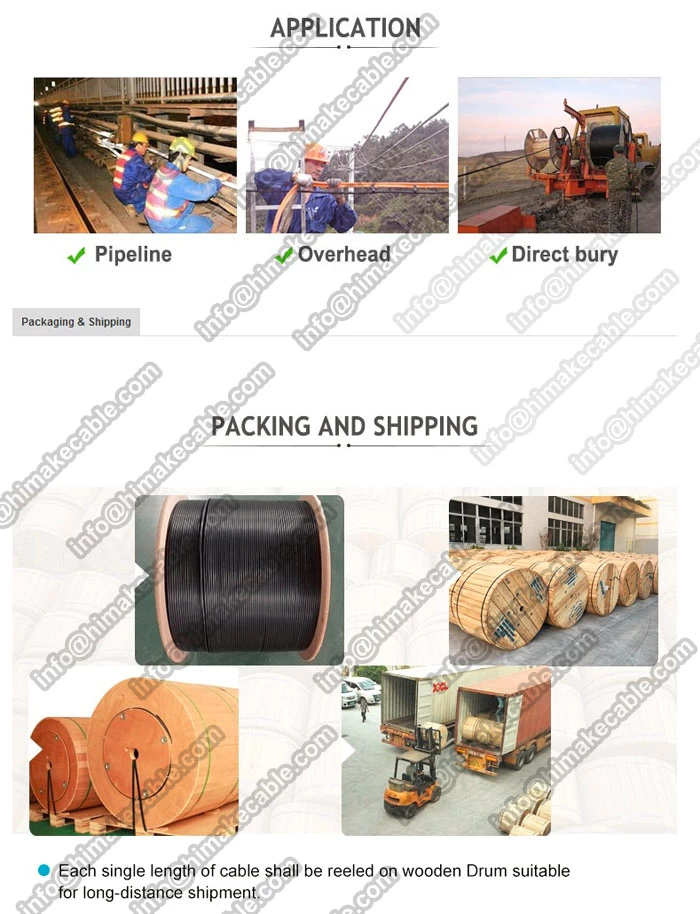

- Shipment: Express, FCL, LCL, by sea or by air

The fibers, 250um, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water resistant filling compound. A steel wire, sometimes sheathed with PE for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminated (APL) is applied around the cable core, which is filled with the filling compound to protect it from water ingress. Then the cable core is covered with a thin PE inner sheath. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

Standard: YD/T 901-2001, IEC60794-1

Product characteristics

1. 2~228 fibers, jelly filled, fiber contained loose tubes

2. Good mechanical and temperature performance

3. High strength loose tube that is hydrolysis resistant

4. Special tube filling compound ensure a critical protection of fiber

5. Specially designed compact structure is good at preventing loose tubes from shrinking

6. Crush resistance and flexibility

7. PE outer sheath protects cable from ultraviolet radiation

8. Good cable watertight.

Adopted to outdoor distribution, even the place with moisture-proof and rodent-proof requirement

Long distance and local area network communication

|

Fiber count |

Cable dia. |

Cable net weight |

Min. bending radius (mm) |

Allowable tension (N) |

Max. crush loading force (N/1000mm) |

|||

|

cores |

(mm) |

(Kg/km) |

Static state |

Dynamic state |

Short term |

Long term |

Short term |

Long term |

|

2-24 |

13.3 |

210 |

12.5D |

25D |

3000 |

1000 |

3000 |

1000 |

|

26-36 |

13.6 |

220 |

12.5D |

25D |

3000 |

1000 |

3000 |

1000 |

|

38-60 |

14.1 |

225 |

12.5D |

25D |

3000 |

1000 |

3000 |

1000 |

|

62-72 |

14.6 |

255 |

12.5D |

25D |

3000 |

1000 |

3000 |

1000 |

|

74-96 |

16.2 |

305 |

12.5D |

25D |

3000 |

1000 |

3000 |

1000 |

Product Advantages

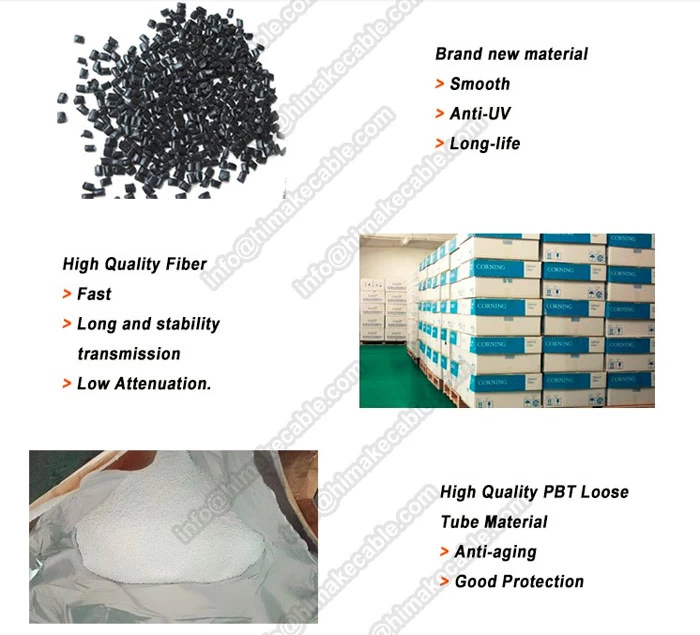

1. The conductor is made of Top quality optical fibers, it has Low dispersion and attenuation, ensuring a very good signal and data transmission ability.

Tel:0086 150 1259 7988

Wechat:0086 1501259 7988

Contact Person:Bill Zhou

PDF Show:PDF